BAODING ZSHC ELECTRICAL CO., LTD.

PRODUCTS

Kiribati Zinc spraying machine

Spray gun working pressure: 0.5Mpa/1.85 m3/min

Output power: 16kw

Maximum output current: 300A 400A 500A

Category:

Product Description

Overview

PTJ-300A high-speed arc spraying machine is a high-efficiency, low-energy high-tech product developed by our company. It uses electric arc as heat source to melt the metal wire, atomize and cool it with compressed air, blow the metal wire to be sprayed into fine particles, and spray it at high speed to the surface of the heat-treated workpiece to obtain the ideal coating.

QDIII-250 type high-speed arc spray gun can be hand-held can also be clamped on special equipment for spraying, wide adaptability.

Features

The flying speed of spraying particles of the QDIII-250 high-speed arc spray gun reaches more than 300 M/S, the axial airflow velocity of the nozzle orifice reaches about 420 M/S, the coating density is more than doubled compared with that of the ordinary electric spray gun, and the porosity is less than 3%. The deposition rate of spraying particles is> 75%, and the bonding strength between the coating and the body surface is high. At the same time, the power supply and the control part are designed into one, making the whole set of equipment more compact. In particular, the use of spray gun remote electric control gas, electric switch, the operation is more convenient, to solve the past must be two people at the same time to operate the labor-consuming phenomenon, and can achieve long-distance, climbing spraying operations and spraying the inner wall of the container. All outgoing lines from the power control cabinet to the spray gun adopt safe air pressure, so the operation is safe and reliable.

Principle:

It is to use two sprayed metal wires as self-consuming electrodes, and the arc burning at the end of the wire will melt the uniformly fed wire, and the molten wire will be atomized into particles with fine particle size and uniform distribution by compressed air flow, which will be sprayed to the workpiece to form a coating. When spraying, two wires that intersect at a certain angle (usually 30 ° ~ 60 °) and are continuously fed are respectively connected to the positive and negative poles of the power supply. Wire end contact with the arc, under the action of the power supply, the arc to maintain a stable combustion, behind the arc point, the high-speed compressed air flow is the melting of the wire atomized into particles, sprayed to the pre-treated substrate surface to form a coating.

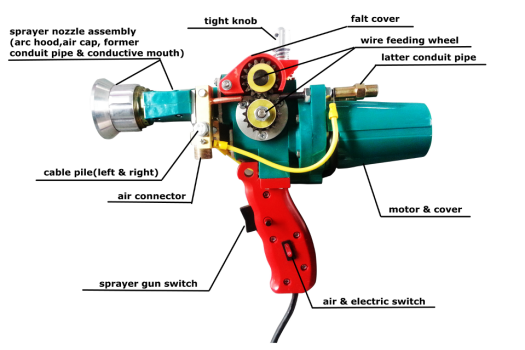

It is an independent component of the spray gun, mainly composed of arc cover, arc cover seat, air cap, air cap seat, front pipe, conductive nozzle, electric pile, etc. \

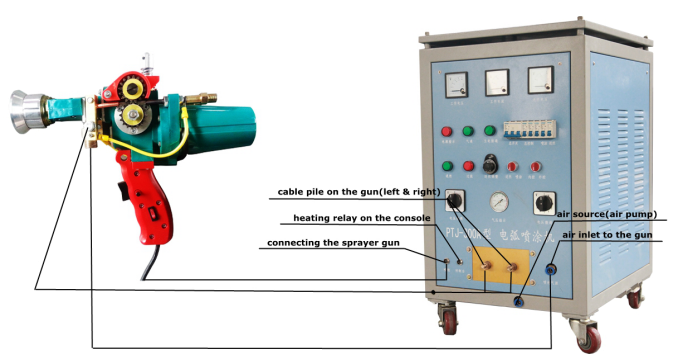

Schematic diagram of installation instructions

: next page